Alterar idioma :

drylin® R - Technical information

Vídeo - Conheça a linha de guias lineares drylin® R

Nosso gerente de produto Anderson Batista apresenta à vocês nesse vídeo a linha completa de guias lineares drylin R, leves, silenciosas, robustas e livres de lubrificação!

Materials table

General specifications

Unit

iglidur® J

iglidur® X

iglidur® J200

Testing method

Density

g/cm³

1,49

1,44

1,72

Colour

yellow

black

dark grey

max. moisture absorption at 23°C/50% r.h.

% weight

0,3

0,1

0,2

DIN 53495

max. total moisture absorption

% weight

1,3

0,5

0,7

Coefficient of sliding friction, dynamic, against steel

µ

0,06 - 0,18

0,09 - 0,27

0,11 - 0,22

pxv value, max. (dry)

MPa x m/s

0,34

1,32

0,33

Mechanical properties

Flexural modulus

MPa

2.400

8.100

2.800

DIN 53457

Flexural strength at 20°C

MPa

73

170

58

DIN 53452

Compressive strength

MPa

60

100

43

maximum recommended surface pressure (20°C)

MPa

35

150

23

Shore D hardness

74

85

70

DIN 53505

Physical and thermal properties

max. long-term application temperature

°C

+90

+250

+90

max. short-term application temperature

°C

+120

+315

+120

min. application temperature

°C

-50

-100

-50

Thermal conductivity

[W/m x K]

0,25

0,6

0,24

ASTM C 177

Coefficient of thermal expansion (at 23°C)

[K-1 x 10-5]

10

5

8

DIN 53752

Electrical properties

specific contact resistance

Ωcm

> 1013

< 105

> 108

DIN IEC 93

Surface resistance

Ω

> 1012

< 103

> 108

DIN 53482

General specifications

Unit

iglidur® E7

iglidur® A180

Testing method

Density

g/cm³

1,05

1,46

Colour

dark grey

white

max. moisture absorption at 23°C/50% r.h.

% weight

0,1

0,2

DIN 53495

max. total moisture absorption

% weight

0,1

1,3

Coefficient of sliding friction, dynamic, against steel

µ

0,05–0,23

pxv value, max. (dry)

MPa x m/s

0,31

Mechanical properties

Flexural modulus

MPa

1.477

2.300

DIN 53457

Flexural strength at 20°C

MPa

22

88

DIN 53452

Compressive strength

MPa

78

maximum recommended surface pressure (20°C)

MPa

18

28

Shore D hardness

61

76

DIN 53505

Physical and thermal properties

max. long-term application temperature

°C

+70

+90

max. short-term application temperature

°C

+90

+110

min. application temperature

°C

-50

-50

Thermal conductivity

[W/m x K]

0,25

ASTM C 177

Coefficient of thermal expansion (at 23°C)

[K-1 x 10-5]

11

DIN 53752

Electrical properties

specific contact resistance

Ωcm

< 1012

DIN IEC 93

Surface resistance

Ω

> 109

< 1011

DIN 53482

DryLin® R - Comparison of the permitted dynamic loads with same diameter

X = speed v [m/s]

Y = F [N] Ø [mm]

A = unsupported shaft - steel/stainless steel

B = unsupported shaft - hard-anodized aluminum

C = supported shaft - steel/stainless steel

D = supported shaft - hard-anodized alum.

Figure 01: drylin® R - Comparison of the permitted dynamic loads with same diameter

Dirt-resistant

DryLin® R linear plain bearings

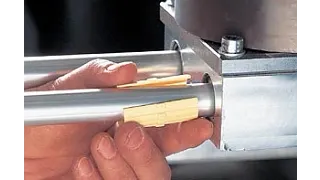

The cylindrical standard bearings consist of a replaceable liner made of iglidur® J, which is clipped on an anodized aluminum adapter with positive-fit. The axial securing of the liner is carried out by a snap ring groove.

The drylin® linear plain bearings made of solid polymer are available in identical dimension. They are completely made of wear-resistant iglidur® J and offer distinct cost and technical advantages. Applications that use machine parts chiefly made of stainless steel, for instance food and filling equipment, are well-suited for the use of solid polymer bearings. A further weight-saving is also obtained.

Both versions are designed for the installation in housing bores with the tolerance H7. The mounting is done like in ball bearings with circlips according to DIN 471/472.

The thin design of the type 02 cylindrical linear plain bearings is press-fitted and/or pasted in the H7 housing bore. Standard commercial 2-component adhesives can be used for this purpose.

**

Dirt, dust, fibers**

An important feature of all the available linear bearings is their tolerance of dirt. For most systems the application of wipers or seals is recommended for even low dirt accumulation.

No other system features such a high safety with dust, lint balls and coarse dirt as drylin®. The abandonment of lubricant as well as the special design of the bearing surfaces with individual glide pads and the connecting elements in between have an advantageous effect in environments with dirt accumulations. Dirt, even when it appears wet on the shaft, is wiped away by the individual glide pads and pushed back into the contact-less area. The crossbars of the running surfaces of the drylin® bearing then glide on the track wiped clean of all dirt.

**

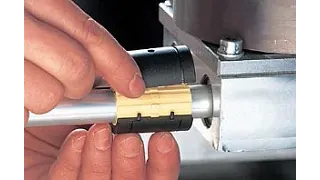

Split linear bearings**

Applications that are on the threshold of technical feasibility or in extremely abrasive environments are marked by the regular replacement of the bearing. In many cases, drylin® could multiply the operating time. However, in such applications the replacement of the bearings may be required from time to time. drylin® linear plain bearings can in this case contribute to substantial cost reduction, because only the bearing liner need to be replaced. This often saves costs by more than 90%. In addition the dismantling of the shafts is avoided.

The split bearings are easily pulled out from the housing and opened. The slotted liner can be simply mounted on the shaft. Join the two bearing halves, install - and it's ready. With this product range of split drylin® bearings, installation times can be reduced to a minimum.